Accu-Grind understands your

company can't afford to have a

custom tool supplier that doesn't

provide answers. AGCS has the

solutions to meet your high-speed

milling, thread milling, form milling,

and multi-operation machining

needs.

Accu-Grind produces a complete line of "industry specific" cutting tools such as:

- Ultra precision keyway cutters

- Radial and axial relief cutters

- H.S.S., solid carbide and carbide-tipped cutters

- Aerospace rootform cutters

- Custom thread milling cutters

- Ultra-precision staggered tooth cutters with tolerances to +0.0002"

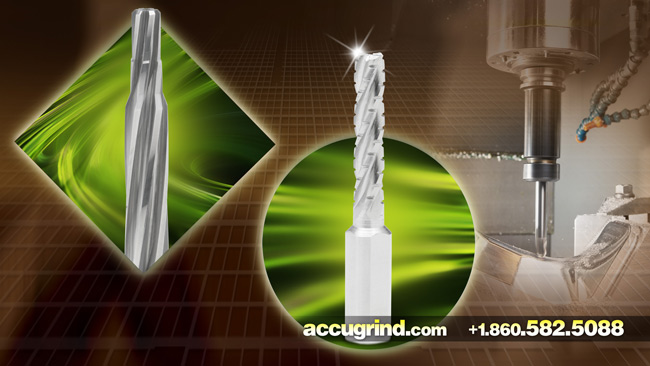

- High-performance endmills made to your specified diameters

- Spiral end and ball endmills

- Radius, ball and taper endmills with 2-8 flutes

|

High Precision

Custom Cutting Tools-

At Accu-Grind,

it begins with

an incredible

design strategy

AND OBJECTIVE:

ISO 9001:2015 CERTIFIED

Accu-Grind guarantees that your tools and parts will be

engineered to the highest performance standards &

precision specifications

We design and build "industry specific"

custom cutting tools:

Turnkey solutions that take you from

concept to final piece production-

while reducing the final cost and cutting your time to market

Accu-Grind Cutter Service, Inc. (AGCS) routinely meets or exceeds customer

demands by employing the best tool design & engineering possible, then streamlining

methodologies in order to produce innovative and cost-effective design-to-build cutting

tool deliverables.

Why Accu-Grind? Companies like yours who are expected to provide competitive

pricing, along with machining performance and productivity, cannot expect to rely

exclusively on general-purpose cutting tools off the shelf. Having AGCS involved in the

application will help you identify those cases where a custom tool truly can deliver the

most value.

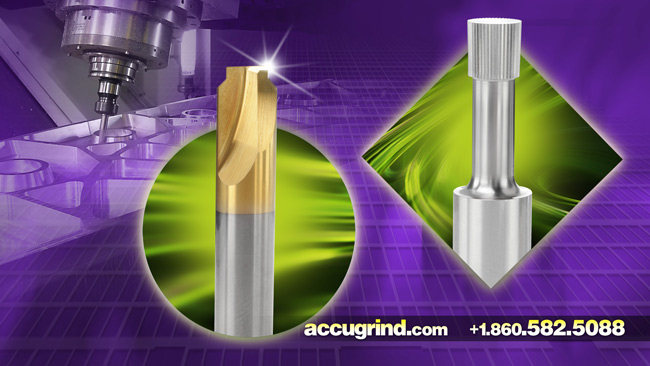

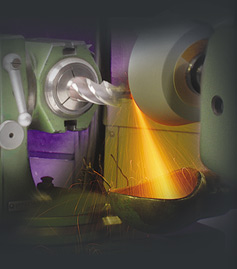

Accu-Grind's design ingenuity, versatility and manufacturing expertise will prove how

we routinely produce mission-critical and efficient cutting tools such as turbine blade

root form cutters. Accu-Grind provides custom tools such as end mills, form mills, thread mills, ball mills & reamers.

We can produce end mills in high speed steel, M42 (cobalt), PM4, High Performance Carbide—and in the most popular sizes and configurations—from 2 to 8 flutes in right hand or left hand cut; ball ends, chamfers, radius ... endless possibilities are available to you! We produce your cutting tools in a variety of metals, including T15PM, M42, M48, M4 and more! Requests? Questions? Comments? Call +1.860.582.5088.

Accu-Grind is not exclusive to one industry, and yet we excel in the aerospace

arena-specifically developing tooling that is used in the production of turbine blade

root forms. Our architecture is helically designed to enhance performance and increase

tool life, resulting in reduced customer cost. Each device is engineered to the highest

performance standards and precise specifications in order to produce an exact duplicate

on time, every time.

Here's how we work: OEMs, engineers and purchasing personnel submit their

product requirements: Accu-Grind reviews each blue print, analyzes the design and

offers improvements, generates an estimate-then delivers custom finished cutting

tools. In most instances, AGCS's engineering team will develop tools that can perform

multiple functions, which, produces your part accurately and in a faster timeframe potentially

cutting your time to market by as much as 500%. You will still be able to

do it your way-ONLY BETTER!

Accu-Grind is unique from the standpoint that a high percentage of our work is

based on our analytical and engineering design capabilities that exceed industry

benchmarks.

Contact us immediately for a complimentary consultation. We'll provide a free

quotation. Simply send us an email or fax us your prints, drawings, files or questions ...

we will bring your ideas or products to reality!

|